How to Overcome Problems of Sourcing and Procurement in China?

While working with Chinese suppliers can be profitable, it can also be challenging. China is far away for most people. Most people have a limited understanding of this country’s culture and language. What are some of the challenges that many people experience when doing business in China? Read our expert tips on solutions how to overcome problems when sourcing in China and to import with more confidence!

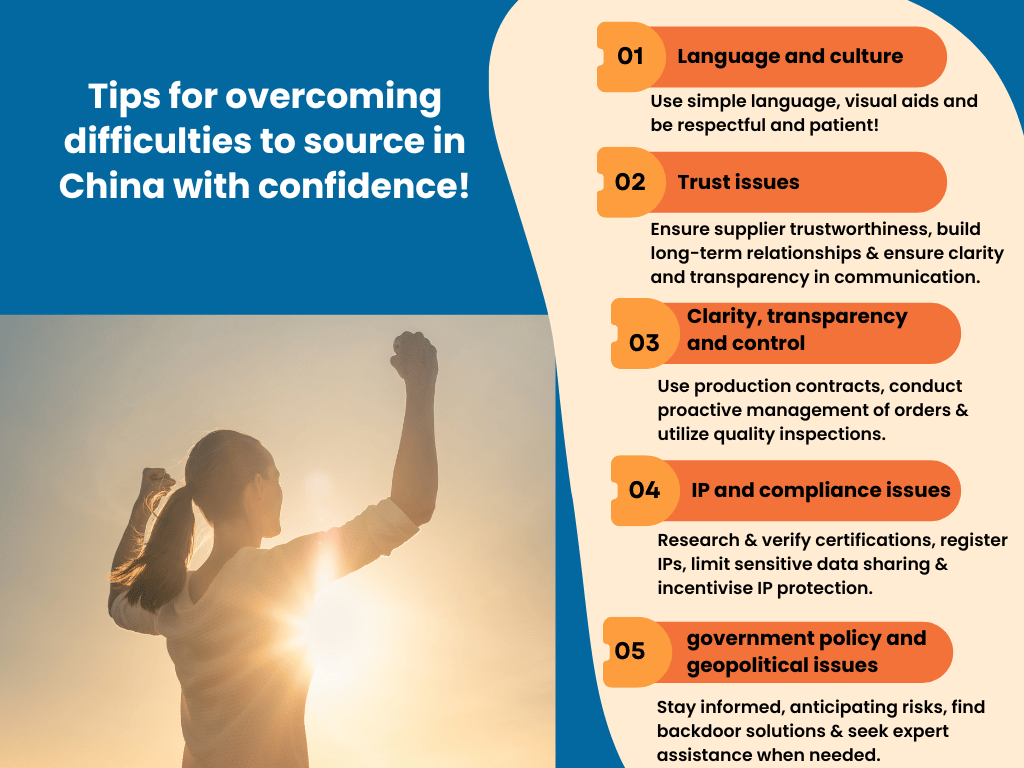

Some major challenges that you may face when sourcing in China are:

- Language barrier

- Cultural differences and communication style

- Trust issues

- Lack of clarity and transparency

- Lack of control over production and quality

- Legal compliance issues in the home markets

- Intellectual property protection

- Effects of government policies and geopolitical tensions

This article will look at these challenges and provides solutions on how to better tackle these issues.

Language barrier

When working with a Chinese manufacturer, many Westerners will feel it is challenging to communicate with their Chinese supplier. Especially if you don’t usually communicate with Chinese people. This may be because of language and cultural differences with China.

One common problem when sourcing in China is the language barrier. Most people who import from China cannot speak Chinese, especially not on a professional level. English will therefore be the most commonly used language. If you do business with a Chinese factory, you can assume that the workers, technical and operational managers and most likely even the boss cannot speak English.

You will probably communicate with one of the company’s sales employees. The primary skill that these salespeople have usually been selected for is their English skills. Even though the sales staff of many factories can speak English on a professional level, there are still many risks that they misinterpret your language while you’re discussing issues with them. They will easily misinterpret issues or make false assumptions during communication. Therefore, you need to be patient. Ensure that the other party has clearly understood all the relevant requirements, specifications and agreements. You can do this, for example, by asking several questions to check for understanding. Or use universal language, such as drawings or sketches.

The fact that only sales staff can speak English well may also prevent open and accessible communication and negotiation between the buyer and the professionals in the factory. In the factory, the operational team may need more help understanding the descriptions, documents and contracts you prepare in English. The people on the workfloor may not understand your descriptions well or are not using them on the work floor, potentially leading to problems and mistakes.

Solution: Communicate in simple and concrete language or seek help to overcome the language barrier

One way to deal with a language barrier is by using simple, concrete language that everybody can easily understand. Use as much as possible documents and descriptions with drawings or pictures or text with a Chinese translation. Another way to deal with the language barrier is to seek support from a professional company that can understand your requirements better and help you deal with language differences between you and the factory staff.

Cultural differences and differences in communication style

Differences in cultural backgrounds, including values, norms, and beliefs, may also impede communication and lead to problems when sourcing in China 1. China has a long cultural history and its model of living and working is fundamentally different from the Western model. When working with Chinese people, you may immediately notice that their communication style is very different from that of the West. It is often difficult to comprehend and interpret the message communicated by both sides. This can lead to risks due to misunderstandings that can ultimately cost lots of money or time.

Some examples of these kinds of misunderstandings are:

“I didn’t understand that the other party didn’t want to proceed with the cooperation. They didn’t tell me.”

“The communication with my supplier didn’t feel real. It looked like a play, and I didn’t understand who they really are and what I could expect from them.”

“They told me they understood everything I had said and that all was possible, but when I received samples, they were not in accordance with my expectations”.

These are three examples of how cultural differences between China and the west, and different communication styles lead to undesirable outcomes and possible loss of money or time. Differences in communication styles happen all the time.

Chinese parties also sometimes use misunderstandings to serve their interests. When you don’t clearly define the terms, conditions and product specifications, the Chinese may interpret them in the most beneficial way for them. Therefore being aware of possible misunderstandings and how misunderstandings would benefit the Chinese side is crucial to avoid undesirable outcomes.

Solution: Learn some basics about culture and communication in China

When sourcing and doing procurement in China, it is helpful to learn some of the background and history of the culture that the other party is from. It may help to understand the other party better, anticipate its behaviour and understand how to make your expectations clear to the other party. Make a strategy for how to communicate with them effectively. This will enable you to avoid language and cultural differences getting in the way of achieving a successful final result for your company. Another option is to find a company specialised in communication with Chinese suppliers. This company can advise you on more effective communication or do the contacting for you and avoid the cultural barriers to get in the way of your success in China.

Trust issues

Effective cooperation between supplier and buyer requires trust. A lack of trust can be a serious problem when sourcing in China. This trust may be lacking on both sides, as distance, cultural differences and language barriers make understanding each other difficult. The lack of transparency and clarity on what’s going on and what to expect from the Chinese side can make it even harder to trust any Chinese supplier.

From the Chinese side, there is a natural distrust when doing business with people that they don’t know (outsiders). The Chinese collectivist culture has a strong “us-versus-them” concept, meaning that anyone within the inner circles of the collective (for example, family or close business partners) can rely on high levels of trust. On the other hand, there is a much stronger risk-averse attitude and stronger distrust of anyone outside these circles than people in the West are used to.

Facing distrust

Foreigners meet the highest level of distrust because the Chinese may not know what to expect from them. You are seldom seen as part of the inner circle. There may also be a natural bias against foreigners because of cultural differences and historical reasons. As a non-Chinese working with Chinese suppliers, you’d better not expect much transparency. Especially at the beginning of the cooperation.

The buyer will inevitably start with the same level of distrust as the Chinese supplier. For Chinese companies, exaggerating, over-promising and even cheating are often acceptable ways to attract new customers. The Chinese, unlike Westerners, might not see these issues as morally wrong as much as they see it as smart business. It will also be more likely that the Chinese side will only partially commit to agreements made with foreign parties, especially oral agreements. These agreements may be considered less valuable and they will easily violate them at any time. If you put too much trust and believe in what your Chinese supplier tells you and promises you, the Chinese side may see this as your weakness. They will likely see you as a weak partner and someone they can take advantage of.

So, lack of mutual trust can be a serious problem when sourcing in China. How is it possible to solve this problem and get into a situation where joint trust levels can increase to achieve constructive cooperation?

Solution 1: Factory selection and due diligence

If you do some essential due diligence during the factory selection process, you can already get more indications of which factories are more or less trustworthy. It is helpful to know if a company has no adverse track record, for example, warnings or penalties in the past. Official business licenses may also verify the accuracy of the information provided by the company on Alibaba or other websites. Moreover, you can verify the information and documents the supplier’s contact person offers. The basic due diligence process can contribute to a greater level of trust. If red flags come up, avoiding cooperation with this company may be advisable.

When visiting the factory, you can get a more accurate understanding of how trustworthy the factory is. You can see with your own eyes how processes operate in the factory. When you use this opportunity efficiently and ask the right questions, you may get a stronger indication of how much you can trust the company. When you know what to expect, you can better shape the cooperation.

Solution 2: Build a long-term relationship

Trust is something in China that you need to build over time. This is the same elsewhere, but developing this trust takes much longer and more effort than in the West. Reasons for this are historical, cultural and the fact that contracts and agreements cannot serve the same (legal) role in China as they do in the West.

Once you have built up trust in China, this trust is a valuable asset, and it may serve you in many ways. You may get better deals and prices, and the supplier may be more open and transparent. Depending on your plans and strategies, you may wish to invest in a long-term relationship with your supplier(s). If you decide to invest in the relationship, you must also get to know the supplier’s boss, his family members, and employees personally. It would require personal interaction rather than emailing from a distance.

Solution 3: Get enough clarity and transparency from your supplier to manage the orders

If trust is limited, you can solve this by knowing exactly what is happening in the factory and following your orders closely. Demanding clear and transparent information is an issue, especially when mutual trust is lacking. Below are some solutions on what to do to get clearer and more transparent information from your supplier.

Transparency and clarity issues

Chinese, in general, and more specifically Chinese suppliers, are not particularly known for their transparency. You may have already noticed this when visiting your local Chinese restaurant. They often hide the kitchen away from view, and many people ask what is happening in that kitchen.

When dealing with a Chinese supplier, it is often not in the supplier’s interest to be transparent and clear about all processes during production. The more they define things vaguely and the fewer written agreements they make, the more flexibility they have to find options and solutions that serve their interests and profitability. They also get a better opportunity to hide the shortcomings of their company.

As a buyer, on the other hand, the lack of clarity and transparency can be frustrating and risky. Questions arise: “Do they actually produce my product in the factory you have seen? Is the factory the same company that you contacted? Are they genuinely able to keep all their promises?”

In order to mitigate risks, you will need to know what is going on with your supplier. A lack of transparency can lead to all kinds of undesirable outcomes. It can lead to quality problems, price uncertainty or unexpected delays, causing cash flow issues for your company. It may also make it harder to trust your supplier. Therefore you may choose to find solutions to get more clarity and transparency from your supplier:

Solution 1: Select a company that communicates clearly from the start

When selecting a company to cooperate with, it may be wise to use the first experience of how the company communicates as one of the selection criteria. Some issues that you could pay attention to are: How do they answer the questions that are relevant to you? Do they confirm answers and promises in writing? How detailed and correct are the quotations and other documents you may receive from the supplier? If the company usually uses relatively open communication, it will often show itself early in the cooperation.

Solution 2: Aim for tangible proof in the form of samples

Even though a lot can be agreed on paper, a touchable sample is a better reference point for clarity. The sample cannot lie. The final sample that the buyer confirms is the “golden sample”. This sample can be used as a reference to judge the quality of the products during and after the production process.

It’s advisable to make sure that the sample is flawless before proceeding. Test the samples for all aspects that are relevant to the product. You set the quality standards for the factory at the point of accepting the final sample.

Solution 3: Work with highly detailed and bilingual written production contracts:

A production contract can define as detailed as possible what both parties expect from the cooperation and the products ordered. Define your expectations for the product’s specifications, functionality and performance in as much detail as possible. When the description is detailed, less ambiguity is left for the supplier to be flexible in producing your products. The same applies to all other negotiated terms (shipping terms, payment terms, delivery terms, etc). Ensure that your contract is bilingual and that the terms are well-defined in the Chinese language and in accordance with Chinese law. This makes the production contract legally enforceable. Giving clarity and making the process transparent are other functions of a production contract, making it less likely for costly problems to occur.

Solution 4: Hands-on management of production orders:

Following the order daily and knowing what is happening at what location during production gives you more clarity and control. If someone can be there during production, you will better understand what the production process looks like and what risks are correlated with this. You can carry out inspections before or during the production process. One of the goals of these inspections is to understand how the factory is really operating. It will be much more difficult for the factory to sugarcoat these processes.

The inspections can help you to get information about processes in the factory. You should ask for updates from a factory regularly. Also, asking for photos or videos as proof is another way to clarify the production process. However, you may still give the factory more opportunities to make things look better than they are if you don’t go there yourself and see things with your own eyes.

A dedicated company in China that you can trust can help you to carry out these processes in China. This allows your company to get clarity and transparency so that you don’t have to worry too much while doing business with your supplier in China.

Having difficulty controlling the quality and progress of production of each order

Lack of control over your suppliers can be another of your problems when sourcing in China. Controlling your suppliers is essential to mitigate the risks of products delivered late or of a different quality than expected. Many things can go wrong in production, especially at the beginning of the cooperation. Quality issues can lead to massive financial losses for your company. Significant delays can lead to problems in your stock and your cash flow.

It is advisable to take a proactive, hands-on approach towards your orders in China to prevent unwanted situations as much as possible. The Chinese management approach of many suppliers is generally reactive. This means that production managers often only start solving problems after they have already occurred and damage is already there, rather than that they proactively prevent these issues. If you find out about production problems too late, you can do very little about them. Especially if production is already finished and even more so when the goods have already shipped out. If you find issues early, it is usually possible to get things fixed, which can avoid lots of financial damage.

How to take a proactive approach towards your suppliers, manage them better and prevent damage to your company?

Solution 1: Build in the right incentives for the factory and write a proactive production contract

A well-defined plan to tackle supply chain risks can help you mitigate potential risks in its supply chain. The production contract anticipates possible scenarios and is designed to prevent these scenarios.

Negotiate a contract with the supplier in which you emphasise the potential risks of issues within the supplier’s control that will affect you. As much as possible, the supplier bears the risks here. Encourage the factory to resolve problems as quickly as possible. An excellent way to do this is to always keep some leverage on the supplier’s side by negotiating favourable payment terms, or other terms that incentivise the factory to avoid problems. In practice, this often means you owe money to your supplier until the final inspection or even until receiving the goods in your country.

When the supplier still needs to receive your money, they will likely listen to your requests. You can use these terms to push and negotiate solutions later on. But the fact that you push these agreements through and you have discussed the scenarios with them is, in most cases, enough to prevent many scenarios from happening in the first place.

Write all these agreements in clear and detailed terms inside the production contract you sign with your supplier. The better you define them, the more enforceable it is and the more vigorous its preventive power will be.

Solution 2: Hands-on daily management of your orders

Even though you may have incentivised the supplier to prevent issues from happening, the reality is that the management style in many factories is very reactive. Often, factory managers and salespeople sit in their comfortable air-conditioned rooms most of the time, not seeing the work on the work floor. It, therefore, requires a hands-on, proactive approach from your end to ensure that production is managed and that you can maintain control over it. Getting control is possible in different ways:

Ask for regular status updates:

You can ask for regular updates about the production status, when the different production processes are planned and how the various production processes are proceeding. In this way, not only do you know what is happening in the factory and you can anticipate earlier if problems occur. If any issues arise, you can push the factory to prioritise to get the problems solved. You also ensure that the product managers are on top of the production to be more in control of the quality and the production planning.

Visit the factory and inspect:

Even better is to visit the factory and observe production on-site or find someone in China to do this for you. This may have several advantages that can help you to control your orders better. In the first order, you can see every step of production and find out which production steps are executed in the factory, what product parts they buy from their suppliers and what processes are happening by hand or machines. This will give a better idea of where the potential risks lie in the production processes and can help to identify more risks in the future.

A second reason to inspect during production is to manage production even more proactively. The advantage of this is that you can pressure the factory’s management to ensure everything goes fine, as they know you can see what’s going on! You can provide feedback to the factory. You can regularly visit the factory to maintain an ongoing dialogue with suppliers about their performance and to improve their performance. If you provide clear and actionable feedback on their performance and opportunities for improvements, it will prevent and solve many problems in production. The physical presence will also show the factory that you are serious about your requirements and have a cooperative approach to improving things, which will help build a better rapport with them.

Solution 3: Quality inspections

Ensure the ordered goods have the desired specifications as formulated in the contracts. You want to ensure the product’s quality before shipping meets your company’s standards. Then inspecting production in China is beneficial. Without proper monitoring of production processes, there is a risk of receiving products of substandard quality. It is the last chance to get still issues fixed because after the goods are loaded, shipped and paid, the factory usually loses most if not all responsibilities for the goods.

Additionally, inspections can help uncover potential problems or issues that could affect the quality and cost of the goods. Inspecting production increases the chances of delivering the right products on time, thereby reducing the risk of financial loss due to defective products.

Products made in China are not always compliant.

If you import goods into your country, you are solely responsible for compliance with the product regulations in your country. This can be a serious problem when sourcing in China. Your factory simply has no real responsibility here, and you cannot hold them accountable. They will sell to you whether or not their products comply with your market regulations. Factories often sell to many places worldwide, and all these markets have their own regulations and standards. For example, Nigeria’s regulations may differ greatly from those in the EU or the US.

The standards are translated into directives of different kinds. You must comply with all the directives for product safety that apply to your products in your market. These standards and directives and the intensity of enforcement and product compliance inspection may differ in different markets. It is common to see Chinese-produced products entering markets without complying with all local regulations.

If your products cannot comply with the regulations, there may be severe risks for your company. You may risk legal consequences such as fines or withdrawals of licenses when your goods are subjected to inspections at customs or later in your home market. Market platforms like Amazon.com may not allow you to sell your goods if you cannot prove that your products are compliant. Finally, many importers would feel uncomfortable selling products with safety, environmental or other issues. So, to avoid problems, you will have to be careful and research ahead of time. You will need to find solutions to ensure that your product is compliant.

Solution: Do your research and check the reports and documentation to be able to draw your own conclusions

Find out what certifications and reports can prove that the product is compliant with your home market. Check and verify the certificates and reports the supplier provides to ensure compliance. Ensure that all certifications are genuine and provided for the same product you are buying and that they are not outdated. Also, check if these test reports and certificates are applicable to your target country.

Many suppliers can provide the correct certifications for the European market and the US. But you can never assume that this is the case. If you find out that certificates are missing, incorrect, or expired, it is your responsibility to take action. You can choose to perform the necessary tests to prove compliance by yourself. You can negotiate with the supplier to get them to perform the needed tests. Alternatively, you can find another supplier to provide you with all the documentation you need.

Uncertainty about intellectual property (IP) protection

Your intellectual property, product design and the manufacturing process you’ve created often set you apart from the competition. That’s why you want to protect your trademarks, patents and product designs and that nobody can steal your idea and market your product as their own. China has long thrived as a country imitating products and business models from abroad. Chinese have often treated intellectual property with a different respect than the West. So how can you trust your Chinese supplier to respect your IPs when you work with them?

There are always risks when doing business in China while possessing certain IP rights. You probably want to mitigate these risks as much as possible, so you should first find solutions to protect these rights.

Solution 1: Register your intellectual property in China so they are legally enforceable

Whether you have registered your trademarks, brand names, product designs or patents in your home country, they are not enforceable as long as you have not registered them in China. After registering your IPs in China, you own legal possession of them. It is a common misconception that intellectual property rights have no value in China or are not enforceable. These days, more patents are filed in China than in any other country. China has extensive IP laws, and legal cases about IP infringement are abundant. Sometimes, a foreign firm sues a Chinese manufacturer, but most of the time, it’s Chinese companies suing each other. You can legally defend your IP rights by registering your trademarks, product designs, brand names and patents.

Solution 2: Make infringing your IPs as difficult as possible and provide incentives to not infringe on your IPs

While legal systems are in place that can protect your registered intellectual property, you probably don’t prefer to rely on China’s legal system to protect your IPs. Foreign companies in China have always had difficulties enforcing their intellectual property rights. Finding your way through the Chinese legal system may be challenging. Finding competent lawyers and starting lawsuits is expensive and time-consuming. Your also ruin your relationships with your Chinese suppliers when you need to sue them. In addition, local protectionism and biases against foreign companies may make enforcing your legal rights even more difficult.

There are two questions that you could ask yourself to mitigate the risk that your intellectual property will be infringed in China and that you would need to go through costly and time-consuming procedures to get your rights:

1: How can I provide as little sensitive data as possible to my suppliers while still making it possible for them to produce my product?

2: How can I ensure it is not in the supplier’s interest to steal and copy sensitive information?

Uncertainty about government policy and geopolitical issues

Global tensions are rising. In the recent past, supply chains have been heavily corrupted by COVID restrictions and in the future, they may be corrupted again by (geo)-political factors. Companies see these risks and want to reduce the chances that these issues may cause problems when sourcing in China.

In China, governments regulate industries strictly and can disrupt supply chains with their decisions. If the government decides what they think is in the general interest, the individual manufacturer has no right to challenge the decision. This means that sometimes whole factories must move or close for a certain period. The lockdowns and restrictions for electricity usage in 2020-2022 are examples of these policies. Other examples include suddenly imposed environmental regulations that halt the operations of factories. This may result in factories being unable to serve their clients as agreed, leading to major delays or cancelled orders.

For foreign investors, government intervention is also an ongoing threat. Interventions may lead to sudden currency fluctuations, restrictions on foreign investors, or other regulations preventing foreign companies from operating normally.

So how can you minimise the risks of geopolitics and government interventions for your supply chain?

Solution: Stay informed, be aware of the potential risks and be able to find backdoor solutions

Risks at the geopolitical level or sudden policy changes in China are impossible to mitigate completely. By staying informed about the latest political developments in China and the policy directions, however, it will be easier to anticipate potential risks proactively. The kind of supplier you choose and its location can also influence potential risks. For example, working with a factory near a city centre will be more likely to be affected by changing environmental regulations than a factory located in an industrial zone. Choosing your supplier wisely and making informed decisions based on the latest policy trends and information can significantly reduce risks.

In addition, you could find backdoor solutions if issues occur. In China, there are always ways to get things done. Often, regulations are ambiguous and not black and white. There is almost always a backdoor solution when something is officially illegal or discouraged. Chinese people are aware of this and use backdoors all the time. They often need to be intelligent, flexible and pragmatic to find the opportunities that are always there. This way of working may seem very shady for Westerners, but with the practical Chinese way of thinking, you can often get things done much more effectively and efficiently in China.

As a foreign importer, it may be difficult to always stay on top of what is happening in China and understand the trends, policies, risks and opportunities. Also, finding unconventional opportunities to get things done may be challenging. Therefore, having a company able to help you with your decisions when things become difficult can be highly valuable.

Conclusion

All buyers experience different problems when sourcing and in China. Depending on your situation, what kind of business you do and what kind of problems you encounter in your sourcing and procurement endeavours, you will need to find your unique strategy and solutions. Sino Import Solution is a company with experience with all these common issues you may face in China. Don’t hesitate to contact us for our advice on your unique situation.