Do you encounter quality issues in China and do you struggle with costly and frustrating misunderstandings? Then production contracting is the China import service you need.

What is a production contract?

A production contract is an agreement between your supplier and you as their client. It defines in detail the terms on how to work together to make and deliver a product.

By signing a production contract, you can clearly define your agreements and protect your company’s interests in China. At Sino Import Solutions, we specialise in creating custom production contracts tailored to your unique needs. Take control of your buying process and protect your business interests with a solid legally valid and strategically formulated production contract.

What problems can production contracting solve?

Many factories prefer working with vague Proforma Invoices instead of clear contracts. Specifying goods in less detail benefits the supplier’s flexibility, not yours. You trust the supplier to make a sound decision for every undefined specification or agreement. You put your trust in people whose main objective is to save money and dodge problems. They may find ways to deliver cheaper materials, and packaging or don’t comply with your expectations in another way.

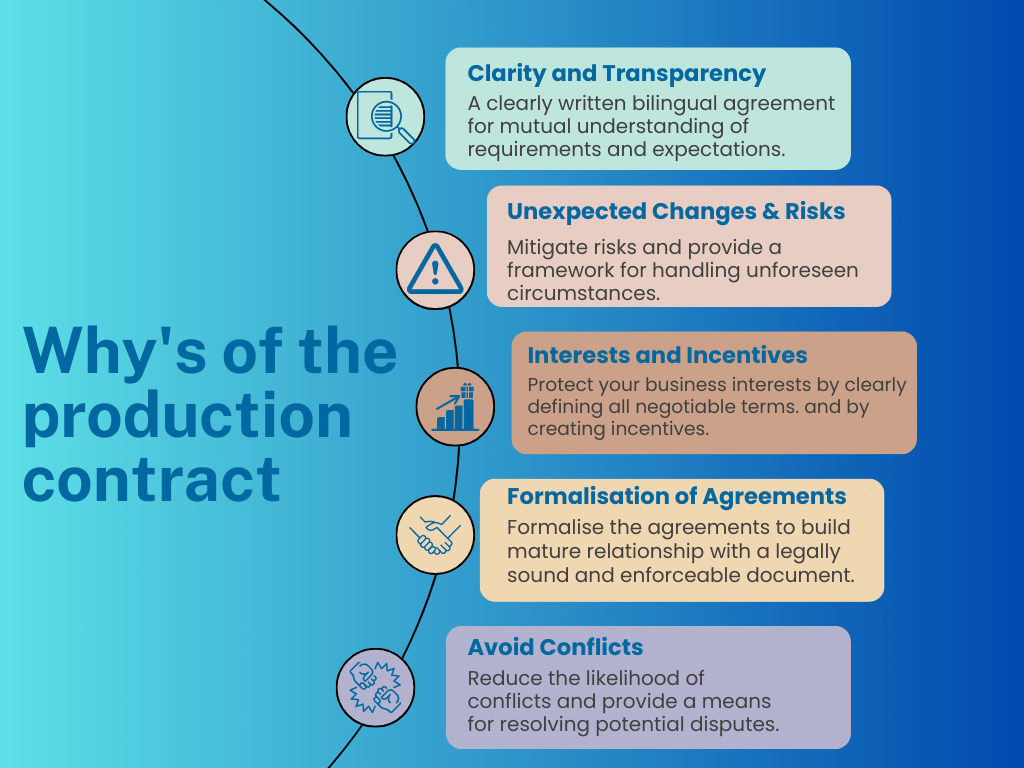

There’s a better way. By signing a production contract, you can clearly define your agreements and protect your company’s interests. This crucial step ensures a smoother and more profitable transaction while avoiding costly delays, misunderstandings, and quality issues. Don’t trust your buying process to chance – take control with solid production contracting.

What do we do?

We can help you create a customised contract suitable for your China manufacturing operations. We have a standard process for drafting a production contract. However, we use a different approach for every client working with another factory and other products. So we will customise every contract to serve your unique needs and company goals.

1: Define the product

When you buy a customised OEM or ODM product, you need to specify the requirements. But even if you purchase a standard item, don’t purely rely on the supplier to judge specifications. We communicate with the supplier (also with the technical managers in the company, since they are much more familiar with the technical details than the salespeople) about the different options and will work with you to precisely define the product specifications. To be in control, we determine the specifications by ourself.

We ensure the factory fully understands the specifications and formulate them in a simple way, so the chance of misunderstandings is minimal. Everyone on the workfloor should be able to understand the terms. For clarity, we translate the agreement into clear Chinese terms and use images and sketches whenever helpful.

To stay in control, we will define each specification, measurement, function, and performance to the maximum extent possible. By doing this, we push the factory to try its finest to meet all the standards. In addition, the more detailed the product is defined, the more leverage you will have to solve problems later, when something goes wrong. There will be less opportunity for the supplier to dodge responsibility. You reduce the risk of receiving goods of inferior quality.

2: Define Quality terms as a basis for Quality control

Based on the defined specifications, we describe the quality requirements of the product in as much detail as possible. We make it straightforward for both the factory and the inspector what attention points they need to pay attention to, to ensure that they deliver the right quality. The contracts lay a foundation for effective inspections and quality control.

It pushes the factory to meet the quality requirements, as they can assure that otherwise we will find any problems during the inspections. Quality terms also come with acceptable margins. We set these margins strictly, giving more leverage to anticipate possible negotiations when any problem occurs.

3: Define all negotiable terms

We define all other negotiable terms, ensuring clear agreements with legally valid signatures from both sides. This eliminates the risk of the supplier renegotiating any terms later in the production phase. Some examples of these negotiable terms are:

- Timelines: Define clear timelines for final delivery and possibly delivery at each stage of the production process.

- Production location: Agree on the production location for the main production processes.

- Pricing and shipment terms: Specify the price and the shipment terms, the payment terms, and any additional charges, such as those for moulds.

- Warranties and guarantees: Specify any warranties or guarantees offered by the producer or manufacturer, including refund policies, quality guarantees, or product warranties.

- Address confidentiality and ownership: Include clauses protecting intellectual property rights and ownership.

4: Define the risks and define “what-if” scenarios to mitigate the risks.

We formulate “What-if scenarios” for scenarios that could turn out wrong. Responsibilities will be clearly outlined and defined: What are the roles and obligations of each party? What will happen if anything goes wrong? It ensures the supplier knows its responsibilities and makes them meet them. When scenarios are well-defined, less time is needed to negotiate when anything happens. We will analyse what might occur during production or delivery when drafting the contract. We will expose the risks and mitigate them when possible.

5: Negotiate new terms with the supplier and ensure that all terms are agreed upon

If we find that some terms have yet to be agreed upon clearly, we will discuss these terms with you. We can help to negotiate these terms with the factory.

By defining the all negotiable terms, we have already done thorough preparation by this time. We have analysed your goals, the product, market conditions and manufacturing process to define your position and find leverage. This allows us to create incentives to motivate suppliers to agree with the terms.

During negotiations, we build rapport while maintaining strict professionalism. Our aim is to create constructive solutions that serve your business and satisfy the supplier as well.

Our negotiation principles:

In order to get the best results, we always negotiate on the following principles:

- Be strict, professional and transparent: We ensure the agreed terms are clear, specific, and formulated in written terms. We will not accept oral agreements, which can lead to misunderstandings and usually have little value in China’s business culture.

- Ensure quality: Products must always comply with quality demands. This is non-negotiable. We’ll ensure that negotiation results are never at the cost of product quality.

- Build rapport and trust: We treat the company we work with respectfully and ensure they don’t lose face unnecessarily. We prepare thoroughly, stay consistent, remain polite, and avoid making unreasonable demands. Being rude during negotiations or letting your partner lose face will ultimately always have a negative effect on you.

- Find constructive solutions: We seek solutions in which both companies get a result that they can work with, and that can bring cooperation forward for both parties. We create room for flexibility and compromise. Examples of terms we can negotiate include price, lead time and delay terms, warranty terms, transparency and access to the manufacturing site, payment terms, mould and tooling costs, problems that can and cannot be accepted, how to solve quality issues, and improvements for the next order.

- Use leverage constructively: We utilise leverage strategically to persuade the supplier to offer you a better deal. We find a balance between mentioning leverage without using it too aggressively and damaging your relationship.

6: Make the contract is legally enforceable.

We ensure that the final contract is bilingual and enforceable under Chinese law, including termination clauses and signatures from all responsible parties.

What do we deliver?

We deliver a legally valid and enforceable production contract that protects your business, avoids conflicts, helps timely delivery, improves the manufacturing process and saves costs in the long run.

Benefits of production contracting for your business:

- Legal Compliance: Signing a production contract checked by a Chinese lawyer, to ensure you and your supplier cooperate following the Chinese manufacturing laws and regulations.

- Protect Your Business: Signing a production contract in China will protect your business interests and ensure improved product quality.

- Avoid conflicts: You can avoid disputes with your supplier since the factory is less likely to dodge responsibility.

- Timely Delivery: A production contract can help ensure the timely delivery of your products and prevent delays.

- Save costs in the long run: A production contract takes a one-time investment but you can use it repeatedly.

- Control your negotiations: Benefiting from our China expertise and guidance during negotiations of terms.

Contact us today to learn more how our custom production contracting service helps you to optimise your China supply chain management.