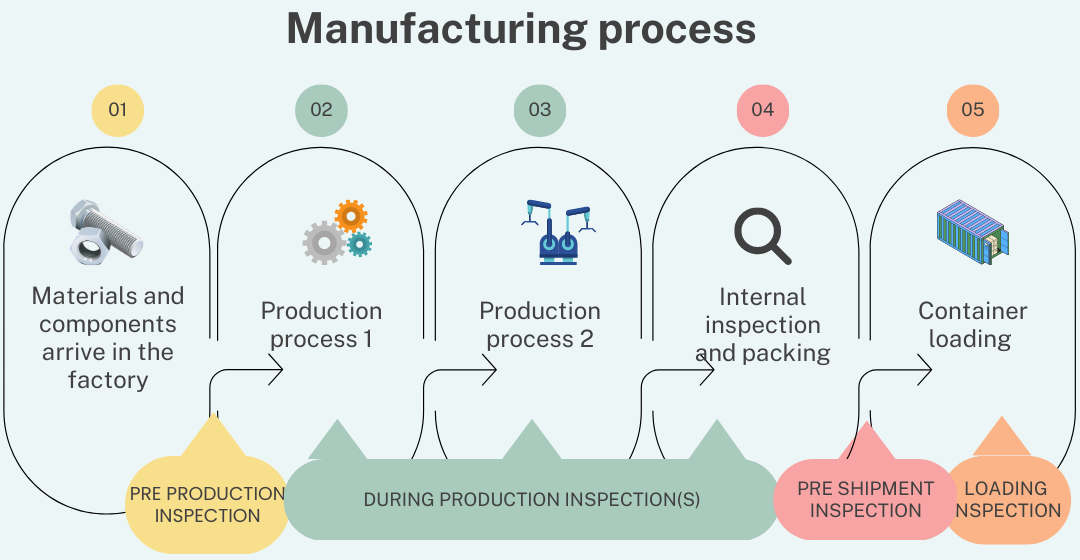

Pre-Production and During-Production Inspections

Our China inspection services include inspections early in the production stage (pre-inspections and during-production inspections). They can be crucial in ensuring your products’ quality and avoiding potential issues with your Chinese suppliers. They allow you to catch quality issues early on, verify product specifications, hold your supplier accountable, and potentially save costs.

Catching quality issues early saves money and time. Inspections allow you to address issues before they become more serious problems. Hence, you won’t need to reject the shipment and negotiate later to resolve the issue. It allows you to cooperate with the manufacturer on the spot. You can push them to adjust their production process to prevent quality problems. Inspections also will enable you to verify that the products meet your specifications and requirements to avoid surprises or disappointments later [1].

What problems are our China inspection services dealing with?

There are many reasons why you want to be in a factory before or during production. Per product or situation, the risks are different; therefore, the risks and how they can be mitigated most effectively must be assessed per individual case. Some of the issues that can be reasons to visit the factory to inspect before or during production are:

1: There are quality issues, or the factory is producing your order for the first time. Our quality control service help you to set a standard, be strict and push them to aim for higher-quality output. You eliminate problems early in the production process.

2: You want to avoid that the quality of the components or materials are unsufficient and affect the final product quality.

3: You have doubts that the factory’s promises about its production may be wrong. For example, you are afraid they may produce in a different factory or on another production line than they promised.

4: There is a part of the production process that needs special attention and, therefore, hands-on management.

5: You are producing a new customized product, and hands-on inspection and communication with the technicians are needed to prevent misunderstandings and problems.

Our China inspection services include:

1. Assess the risks and choose the critical control points for inspection

We will first assess your product’s production process and identify, evaluate, and prioritize potential risks. By conducting a thorough risk assessment, we identify potential quality risks and formulate strategies to reduce those risks. It can help to consistently ensure that your products meet your quality standards and avoid quality-related issues that could impact your business.

We will evaluate earlier quality problems and what point in the production process caused them. Then, we’ll work with the factory and assess what potential risks may impact product quality. We will determine what impact this may have on the final product and how likely this will occur. Risks can be associated with the materials and components used, production processes, factory conditions, or how carefully workers handle your product.

Our analysis can help to prioritize risks based on their likelihood and impact. Based on this, we can develop a risk mitigation strategy. You can focus on planning inspections to address the most critical risks. We can conduct the following quality control inspection services to mitigate risks:

- Pre-production inspection: Inspect if all materials and components comply with your quality standards before production

- During production inspection: Inspect the output of the most vulnerable production processes or the outcome of the first finished products.

- Pre-shipment inspection: Inspect the finished goods to ensure their quality before they are shipped and paid

- Loading inspection: In some cases, the loading of the container is sensitive. We can check onsite whether the loading is carried out carefully.

2. Execute the inspection

The details in the execution of pre-production or during-production inspection depends on the situation and the risks we try to mitigate.

Pre-production inspection

Raw materials and essential components are required to create a product. Materials and components largely determine the final product’s quality. Products such as electronics, toys, and apparel are often subject to pre-inspection to ensure quality and safety standards. For these kinds of products, components and materials are essential. Quality failures with these raw materials or parts will therefore result in quality failures in mass production.

Our inspector will usually spend one day inspecting the materials and components that may influence your product’s quality. We will note down the failures and problems we find during the inspection. We will take videos and photos to report the inspection results. It helps you decide whether the factory can start production.

In addition, when we visit the factory, our inspection services in China include motivating the factory to improve. We believe that by working with the supplier to boost their performance, we can improve the long-term performance of the factory and make the supply chain more efficient and effective overall.

Additional activities in the factory during our inspection day:

- We give detailed feedback on the inspection results. We find out the causes of the failures and discuss possible solutions with the factory.

- We discuss the production and final product requirements and ensure production management understands all needs. It is especially relevant when producing items for the first time or when customization is involved.

- We discuss critical quality risks with the factory during production. We discuss the attention points with the production manager, technical manager and QC staff on how to inspect during production and finished products.

- We check the production line and guide the supplier in improving their processes and meeting the buyer’s requirements.

- We can represent you and discuss any other issues relevant at that moment.

Our China inspection services get you in control the process from the beginning and avoid many problems.

During-Production inspections

One or more production processes may contain high risks and significantly influence the quality of the end product. In this case, you could choose to implement an inspection during the production. We can help you decrease the risk of finding quality failures after they have become difficult to fix. When you find a substantial problem during the final inspection or after shipping, getting the problems solved will be complicated and time-consuming. If this can be prevented, it can save your company a lot of money and time.

Our inspector will usually spend one day inspecting the target production process and the quality of the outcome of that process. We will note down the failures and problems we encounter during the inspection. Clients often schedule this inspection after the first batch of units have finished. We can inspect and immediately halt production if we find any structural problems with the output. We will take videos and photos of all problems and issues so that we can report the inspection results to you. It helps you decide how the factory can proceed.

Additional activities in the factory during our inspection day:

- We give detailed feedback on the inspection results. We determine the causes of failures and discuss possible solutions with the factory.

- We inspect how workers treat and handle your products. If we see improvement points that can improve quality, we’ll instruct the workers directly to improve.

- We discuss the working environment. We discuss how production managers can do more to ensure quality output.

- We discuss the internal quality control process with the production manager and the QC staff and guide them to pay attention to the main focus points.

- We can represent you and discuss any other issues relevant at that moment.

In this way, you have more control over the production process and can use this hands-on measure to prevent quality risks.

What you receive from our China inspection services?

We deliver an extensive report providing all the relevant inspection data. We provide additional photos and videos to give you the most transparent data. Additionally, we will report any further findings during the inspection so that you can control the production. It can help you make informed decisions about how to continue.

- You will receive an extensive report with failure rates and details of the problems.

- You will receive all relevant photos and video materials of the results from the production process or materials/components and the factory environment.

- We will provide you with possible solutions to problems during the inspection and the outcomes of any discussions in the factory.

- We will describe our actions to motivate the factory to deliver the highest possible quality output.

The benefits of our China inspection services for your company:

- We help you prevent inappropriate materials or components used in the product or prevent poor production processes. This could lead to quality or compliance problems.

- We help you save time and money by detecting problems early.

- Our constructive attitude means we are always looking for improvements in output quality.

- We prevent misunderstandings by ensuring that all agreements are understood and that everyone in the factory knows the expected quality standards.

Contact us today to discuss how our China inspection services can help your business succeed in China.